USED OKUMA MB 56 VB VERTICAL MACHINING CENTER

USED OKUMA MB 56 VB VERTICAL MACHINING CENTER

Location:Cologno Monzese, Italy

Description

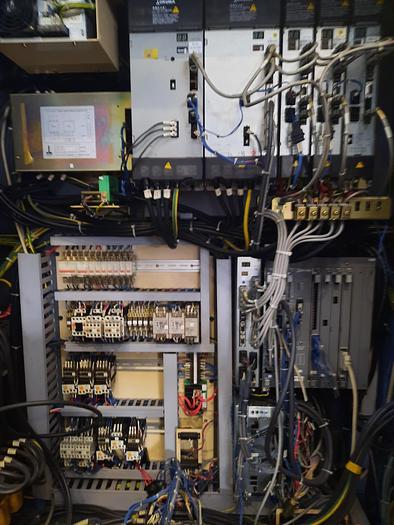

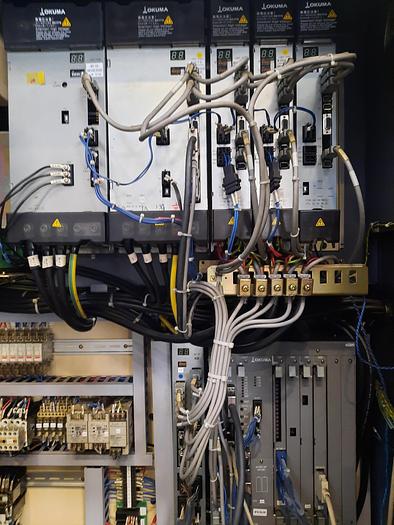

The used Okuma MB 56 VB vertical machining center is a high-performance machine designed for machining operations.

precision milling. Equipped with an OSP 100M control unit, this model offers advanced options such as

through-spindle coolant at 20 bar, a chip conveyor, and a rotation capacity of up to 12,000 rpm

rpm with a BT 50 spindle attachment.

The machine offers a useful working surface of 1,300 x 560 mm and supports a maximum load of 900 kg. The strokes

The axes are 1,050 mm (X-axis), 560 mm (Y-axis), and 460 mm (Z-axis). Rapid feeds reach 40 m/min.

on the X and Y axes, and 32 m/min on the Z axis, with maximum working feeds of 32,000 mm/min. The precision of

positioning is ±0.004 mm, ensuring high quality in precision work.

The Okuma MB 56 VB has a quick tool changer with 32 stations and supports tool holders compliant with BT MAS standards.

With a total weight of 6,900 kg and a maximum height of 2.75 metres, this machine represents a robust and

reliable for advanced production needs, maintaining small footprint for installation in laboratories

industrialists.

Specifications

| Manufacturer | OKUMA |

| Model | MB 56 VB |

| Year | 2005 |

| Condition | Used |

| Stock Number | 00011 |

| Usable surface | mm. 1.300 x 560 |

| Height from the ground | mm. 800 |

| Permitted load | kg. 900 |

| 18mm T-slots | n. 3 |

| Step | mm. 125 |

| X-axis travel (table) | mm. 1.050 |

| Y-axis travel (slide) | mm. 560 |

| Z-axis travel (spindle head) | mm. 460 |

| Distance between table and spindle attachment | mm. 180-630 |

| Rapid advances X – Y axes | m / min. 40 |

| Rapid Z-axis advances | m/min. 32 |

| Max work progress X – Y – Z | mm/min. 32.000 |

| X – Y – Z axis positioning accuracy | ± mm. 0.004 (Std JIS) |

| Repeatability of X – Y – Z axis positioning | ± mm. 0.0015 / 100 (Std JIS) |

| Spindle cone attachment | BT 50 |

| Tool holder type | BT MAS |

| Spindle revolutions | rpm. 50 ÷ 12.000 |

| Continuously variable speed ranges | n° 1 |

| Max power available | KW -20/15 |

| Distance between spindle attachment and table top | mm. 180-630 |

| Tool stations | no. 32 |

| Management | Random |

| Tool holder attachment | BT 50 |

| Tie rod | MAS P2 special |

| Tool change time (adjacent) | sec. 1.2 |

| Max diameter of adjacent tool holders | mm. 90 |

| Max diameter non-adjacent | mm. 125 |

| Max. tool holder length | mm. 300 |

| Max weight of single tool holder | kg. 18 |

| Max Height | m. 2,75 |

| Max. floor space requirements | m. 2,55 x 3,00 |

| Machine weight | kg. 6.900 |